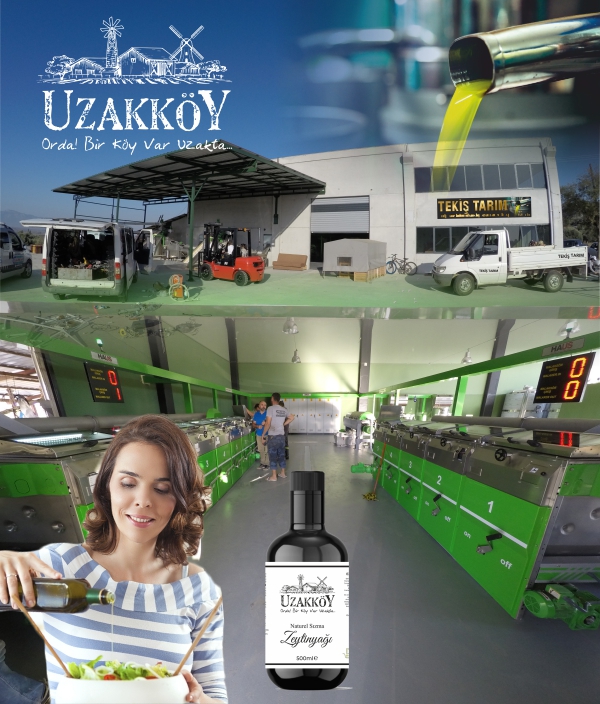

OUR PRODUCTION PROCESS

Nature’s Purity, Untouched by Hands

Uzakkoy olive oils offer a unique flavor where purity and quality converge. Our olives, harvested from our own groves at peak ripeness, are processed at the optimal time. Our production process is designed to preserve the olives’ natural essence, delivering the purest olive oil to your table.

Our olive oil is produced using a continuous system in a modern, hygienic facility, untouched by hands. In this system, olives undergo cleaning, crushing, kneading (malaxation), and oil separation. Quality and purity are meticulously maintained throughout production. Our olive oils are stored in special stainless steel tanks and filtered before bottling.

Uzakkoy olive oil is a delicate, extra virgin olive oil with an acidity level not exceeding 0.3–0.6, crafted from fully ripened olives transformed into oil using natural methods. This pure, additive-free flavor enhances your dishes with health benefits and rich aroma, boasting high polyphenol and antioxidant levels.

This exceptional product from nature reaches your table untouched. Uzakkoy olive oil carries the essence and purity of ancient olive trees to your meals.

Purity and Flavor from Nature.

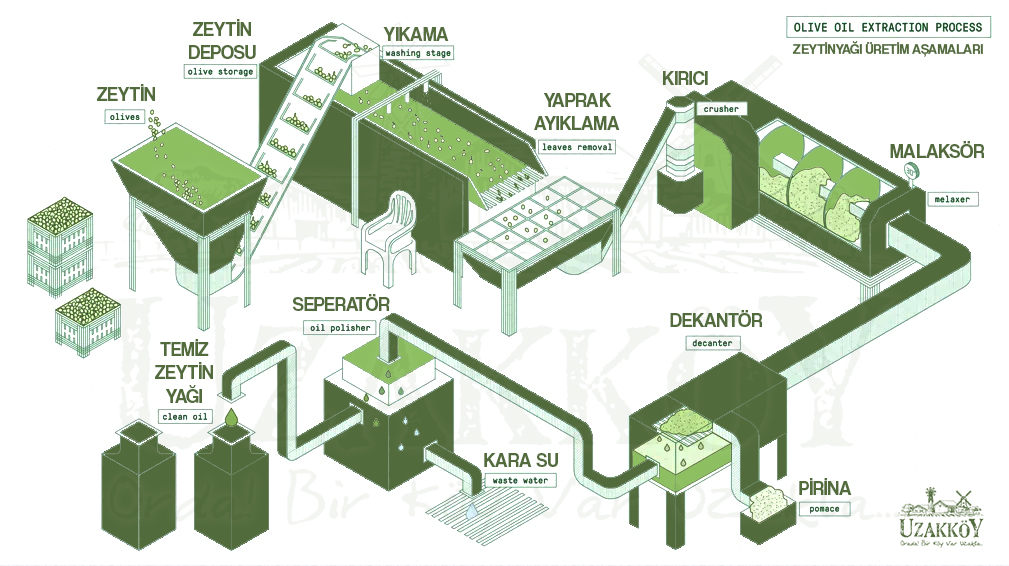

At Uzakkoy, we use cutting-edge technology to preserve the purity and quality of our olive oil. In our groves in Didim Akkoy, we carefully cultivate fully ripened olives, which are processed untouched in our modern olive oil factory in the same village using a continuous system. Continuous olive oil extraction is a widely used modern method that ensures hygienic and efficient processing. Olives undergo cleaning, crushing, kneading (malaxation), and oil separation, with quality safeguarded at every step.

CLEANING

Olive cleaning is crucial for enhancing oil quality and ensuring equipment safety. Olives are washed in automated machines to remove foreign materials like insects, leaves, twigs, stones, and soil.

CRUSHING

Cleaned olives are transported to the crusher via automated conveyors. While traditional systems use granite stone mills, continuous systems employ metal crushers suited for automation, turning olives into a fine paste.

KNEADING (MALAXATION)

The olive paste from the crusher is kneaded in a malaxer at 20–25°C for up to 30 minutes. This process separates the oil from olive cells, preparing the paste for easy oil extraction.

OIL SEPARATION

The olive paste is transferred from the malaxer to a decanter, which uses centrifugal force to separate water (black water), pomace (pirina), and olive oil. The oil is then sent to a separator, where it is fully separated from solids and filtered.

POST-PRODUCTION STORAGE

Our olive oils are stored in special stainless steel tanks and bottled in glass, tin, or specialized plastic containers to maintain top quality, ensuring they reach your table in their purest form.